For those who aren’t familiar with automotive or hydraulic systems, the term “banjo bolt” might sound a bit strange. But for those who work on or maintain these types of systems, the banjo bolt is an essential component that plays a key role in keeping everything running smoothly. So what exactly is a banjo bolt, and what is its purpose?

What is the purpose of a banjo bolt?

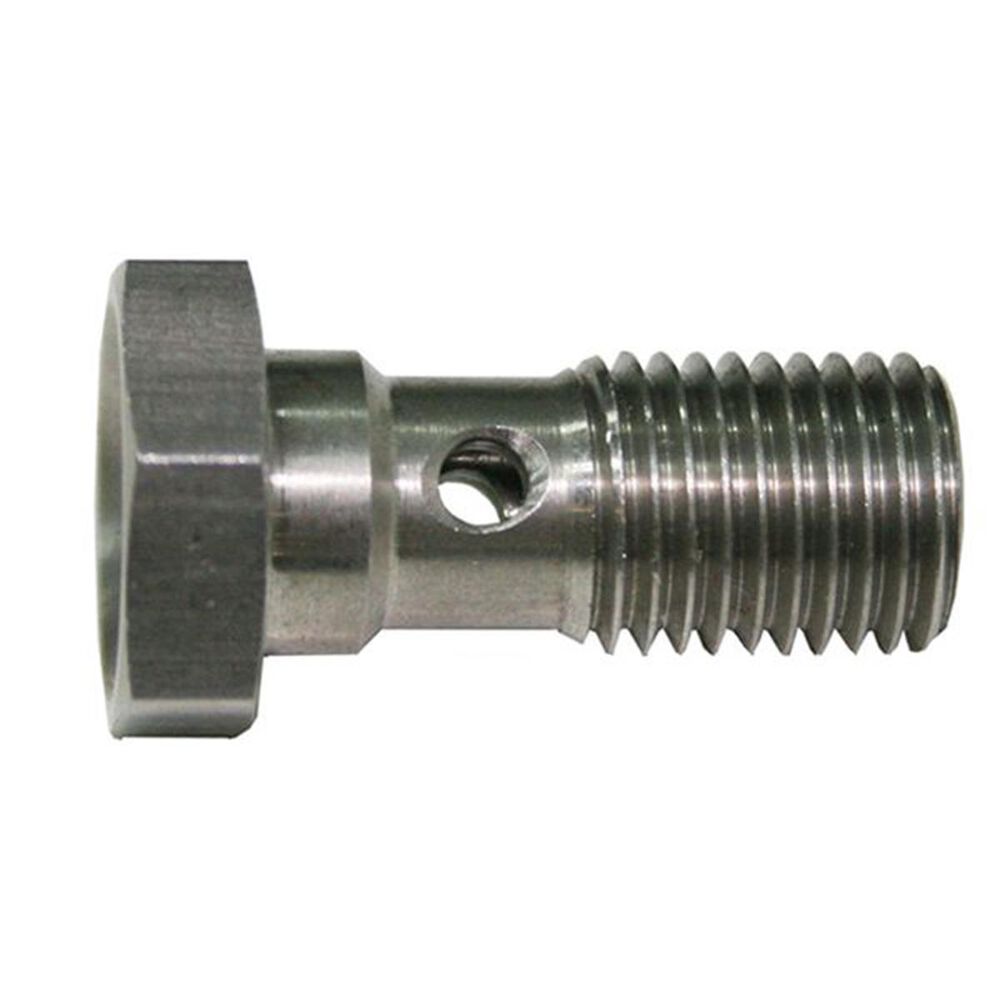

At its most basic level, a banjo bolt is a type of fastener used in hydraulic systems to connect hoses, pipes, or other components. The bolt itself has a hollow, cylindrical body with one or more holes drilled through it. These holes are typically located at a right angle to the bolt’s main body, creating a “banjo” shape that gives the bolt its name.

The main purpose of a banjo bolt is to allow fluid to flow through the hydraulic system while also providing a secure connection between components. In most cases, the bolt is used to connect a hose or pipe to a hydraulic pump or valve, allowing fluid to be transferred between different parts of the system. The holes drilled through the bolt allow fluid to flow through the bolt and into the connected components.

One of the key benefits of using a banjo bolt is that it allows for a more compact and streamlined hydraulic system design. Because the bolt can be positioned at a right angle to the hose or pipe, it takes up less space than other types of connectors. This can be particularly useful in tight spaces or complex systems where there isn’t a lot of room for bulky connectors or fittings.

Banjo bolts also provide a more secure connection than other types of fasteners. Because the bolt is typically attached to a hydraulic pump or valve with a special fitting or adapter, there is less chance of the connection becoming loose or leaking fluid. This is particularly important in high-pressure systems where even a small leak could cause serious problems or damage to the system.

In addition to their main purpose of connecting hydraulic components, banjo bolts can also be used for other functions. For example, in some cases, the holes drilled through the bolt can be used to monitor fluid pressure or temperature within the system. This information can then be used to help diagnose potential issues or optimize system performance.

Banjo bolts can also be customized to fit specific system requirements. For example, bolts can be made with different hole sizes or angles to achieve specific flow rates or pressure levels. Additionally, bolts can be made from a variety of materials to suit different applications, such as high-temperature or corrosive environments.

Overall, the banjo bolt is a crucial component in many hydraulic systems. Its unique design allows for efficient fluid flow while also providing a secure connection between components. Whether used in automotive, industrial, or other types of hydraulic systems, banjo bolts play an important role in keeping everything running smoothly and safely.

Why is it called a banjo bolt?

The term “banjo bolt” refers to a specific type of bolt used in various mechanical applications, particularly in the automotive industry. The name is derived from the bolt’s appearance, which resembles the shape of a banjo musical instrument.

A banjo bolt typically consists of a hollow bolt with a cylindrical portion in the middle and a flared end. The flared end has one or more holes through which fluid (such as oil or brake fluid) can flow. The bolt is designed to connect a fluid-carrying line to a component, often in a way that allows the fluid to change direction. The flared end with holes resembles the body of a banjo, leading to the name “banjo bolt.”

Common uses for banjo bolts include connecting brake lines to calipers in automotive brake systems. The design allows for fluid to flow through the bolt, making it a crucial component in systems where the direction of fluid flow needs to change.

The term is specific to this type of bolt, and while the name might seem unrelated to its function, it has become a standard term within the automotive and mechanical engineering contexts due to the distinctive appearance of the bolt.

How does a banjo bolt work?

A banjo bolt is a specific type of bolt designed for use in fluid-carrying systems, such as brake or hydraulic systems in automobiles. It has a unique design that allows it to facilitate the flow of fluid while securely connecting two components. Here’s how a banjo bolt works:

- Hollow Design: A banjo bolt is typically hollow, allowing fluid to pass through its center. This hollow design is essential for applications where fluid needs to be directed or transferred between components.

- Flared End: One end of the banjo bolt features a flared or widened section. This flared end usually has one or more holes drilled through it. The flared shape resembles the body of a banjo musical instrument, hence the name “banjo bolt.”

- Sealing Washers: The banjo bolt is used in conjunction with sealing washers, which are placed on either side of the components it connects. These washers help create a tight seal and prevent fluid leaks.

- Connecting Components: The banjo bolt is inserted through a hole in one of the components, and the flared end with holes is positioned in a way that it aligns with the fluid passage in the other component. The sealing washers are placed on either side of the components to ensure a secure and leak-free connection.

- Tightening: The banjo bolt is then tightened using an appropriate tool, such as a wrench. The tightening force compresses the sealing washers and creates a seal between the connected components.

- Fluid Flow: With the banjo bolt securely in place, fluid can flow through the hollow center of the bolt, passing through the holes in the flared end. This allows for the controlled and directed flow of fluid between the connected components.

Common applications for banjo bolts include connecting brake lines to calipers in automotive brake systems. The design of the banjo bolt is crucial for situations where fluid directionality and secure connections are necessary, providing a reliable solution in hydraulic and fluid systems.

Free Banjo Tabs

Free Online Banjo Lessons

Learn the Banjo in 24 hours

10 Punk Songs Featuring Banjo

10 Metal Songs Featuring Banjo